[ezcol_2third]

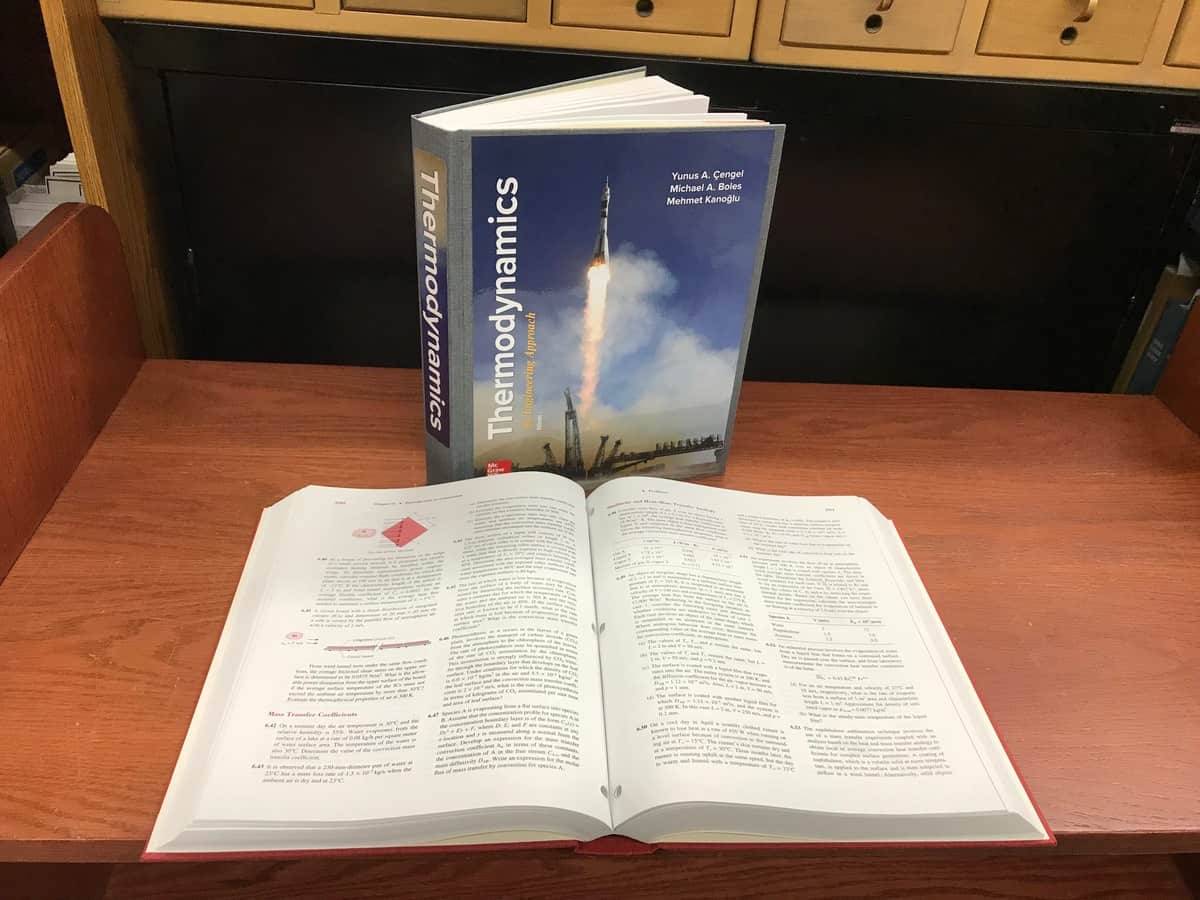

As part of the Preservation Department’s customer service focus, books that are placed on rush are processed faster so that patrons can have access to these materials sooner. Not long before this spring semester started, two unbound loose leaf textbooks needed to be placed on course reserves as soon as possible for student use. Books that are sent to the commercial bindery take four weeks to return, so Conservation Assistant Julie Smith decided to bind these rush textbooks by hand in-house.

The first step that the preservation department took for this in-house binding was to glue the loose leaf pages together using a fan-gluing press. During this step, the pages needed to be perfectly aligned. They were fanned in each direction and sanded to create a rough surface so the adhesive would stick to the paper. The glue was applied carefully, making sure not to miss any areas. Smith noted that the fan-gluing process can be a challenging because there is only one good chance to make sure the spine is glued properly and that the pages stay glued together.

Next the spine was covered with a cambric liner and then a paper liner and left to dry overnight. The following day the text block was ready to be glued into its German lapped case, which consisted of book board held together with heavy paper and covered in cloth. It was then placed in a press to dry. After the binding process was complete, the original textbook covers were glued onto the front. These bindings create a polished final product and allow the book to be much more user-friendly than loose leaf pages.

[/ezcol_2third] [ezcol_1third_end]

[/ezcol_1third_end]